Extended operating range – also ideal for extremely dry environments, even at 0.5% relative humidity

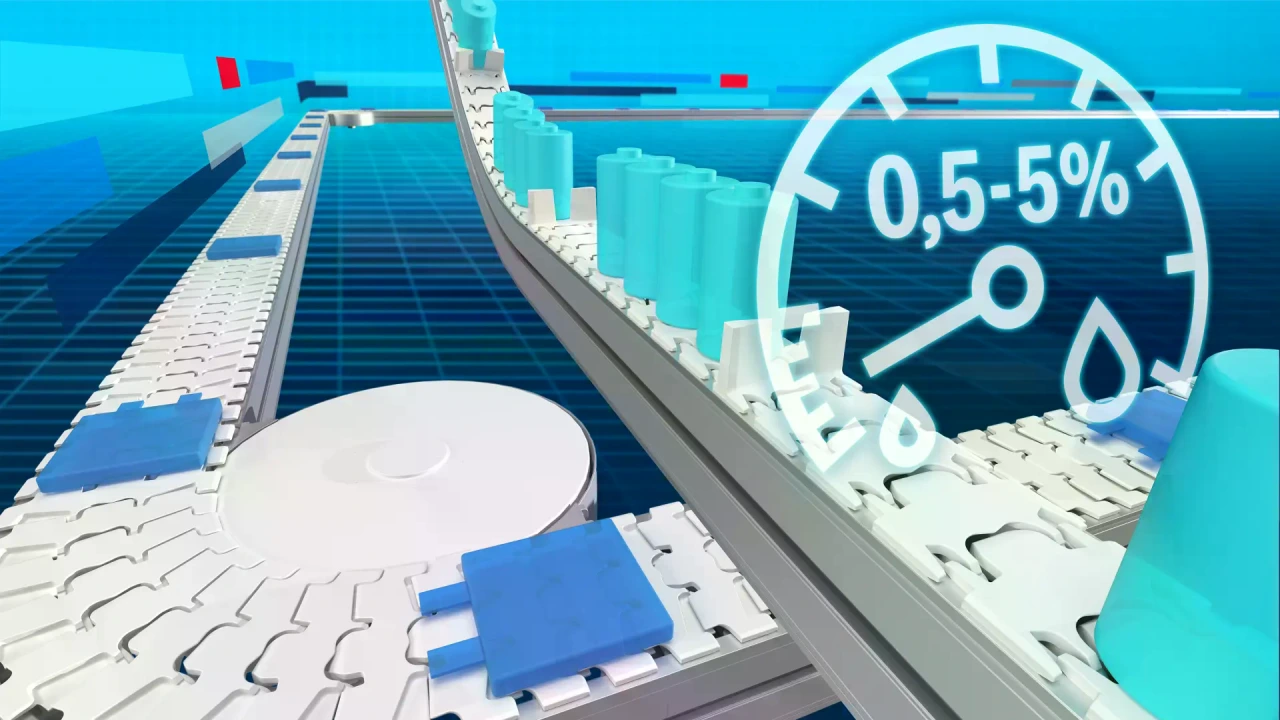

BOOST YOUR PRODUCTION with the VarioFlow plus Chain Conveyor System.

Discover How to Adapt to Constant Change with Flexible Packaging Conveyors

In today’s consumer product industry, companies strive to gain a competitive edge through appealing and user-friendly package designs, leading to constant changes in products and packages. Surprisingly, new choices in packaging conveyors can help companies create a more sustainable packaging system, offering the flexibility companies need.

Today, user requirements for transport solutions are more demanding than ever. With the VarioFlow plus, Bosch Rexroth offers you a high-performance, standardized and versatile chain conveyor system. Create your custom conveyor solution from our extensive modular system. Even in close quarters and in the most demanding spatial conditions, VarioFlow plus can meet any challenge.

Our System at a Glance

With its machine interlinking and product transport, the VarioFlow plus is suitable for a wide range of industries, including

- food and packaging

- healthcare

- automotive and electrical

- Direct and indirect product transport in horizontal and vertical configurations

- Cost-effective: Rolling friction in the horizontal curves enables longer distances & requires fewer drives

- Longer service life and reduced downtimes: Machining-free sliding surfaces reduces wear and tear

- Space-saving: Horizontal curve radius for all sizes

- Fast planning, project planning and visualization with MTpro

- Extensive modular system & high degree of customization options

Products

Aluminum system

Economical basic version

- Open and closed profile version

- Internal groove for attaching main components such as drive, diverter and curves

- External groove for mounting side guides, supports or other accessories

- FDA-compliant materials and stainless steel ball bearings with food-grade grease filling

Technical key data

- Product weight: up to 3 kg / 34.5 mm

- Speed: up to 120 m/min

- External groove for mounting side guides, supports or other accessories

- Chain width: 65-320 mm

Stainless steel system

Suitable for higher hygiene requirements

- Compact clean section profiles minimizese possible deposit points

- Stainless steel glide bars enable use even in abrasive environments

- FDA-compliant materials and stainless steel ball bearings with food-grade grease filling

Technical key data

- Product weight: up to 3 kg / 34.5 mm

- Speed: up to 120 m/min

- Chain width: 65-320 mm

ESD system

Avoid electrostatic charge with a combination of Aluminum, Stainless steel and special ESD components

- Components and parts suitable for use in an EPA (Electrostatic Protected Area)

- Conductive components

- Conductive connection technology

- No additional grounding straps

Technical key data

- Size: 65 mm and 90 mm

- Max. chain tensile force: 600 N

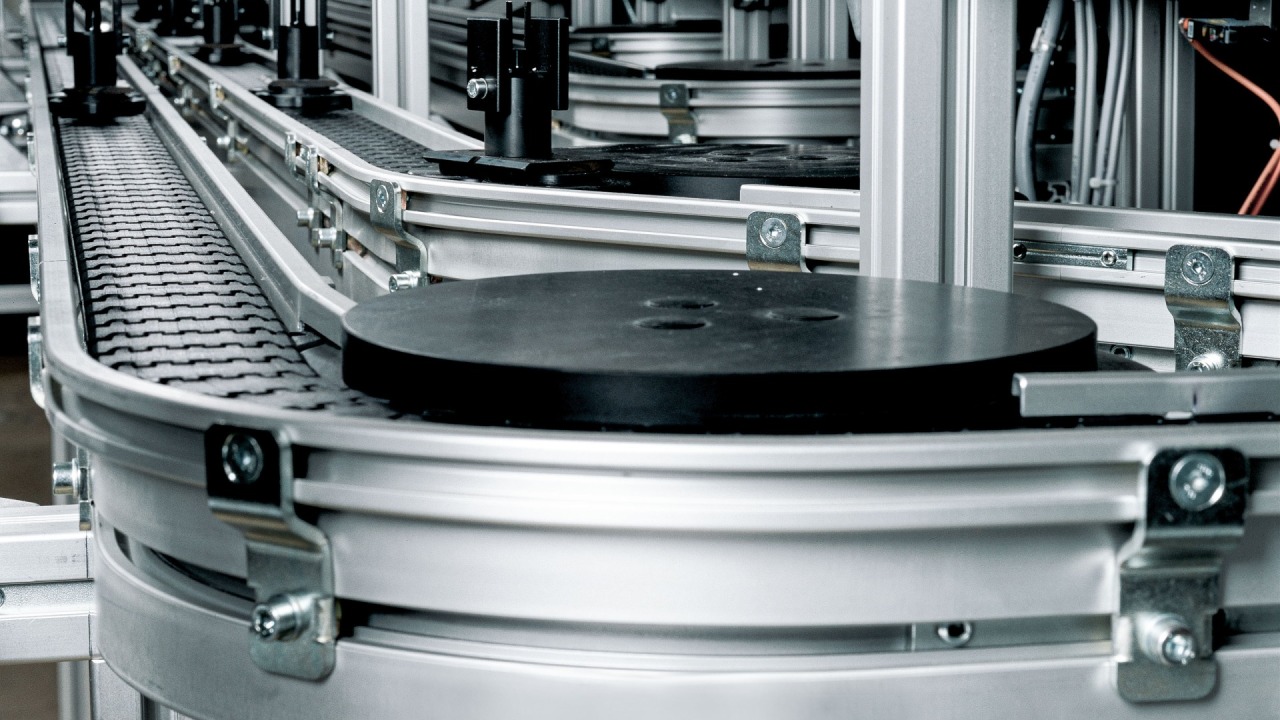

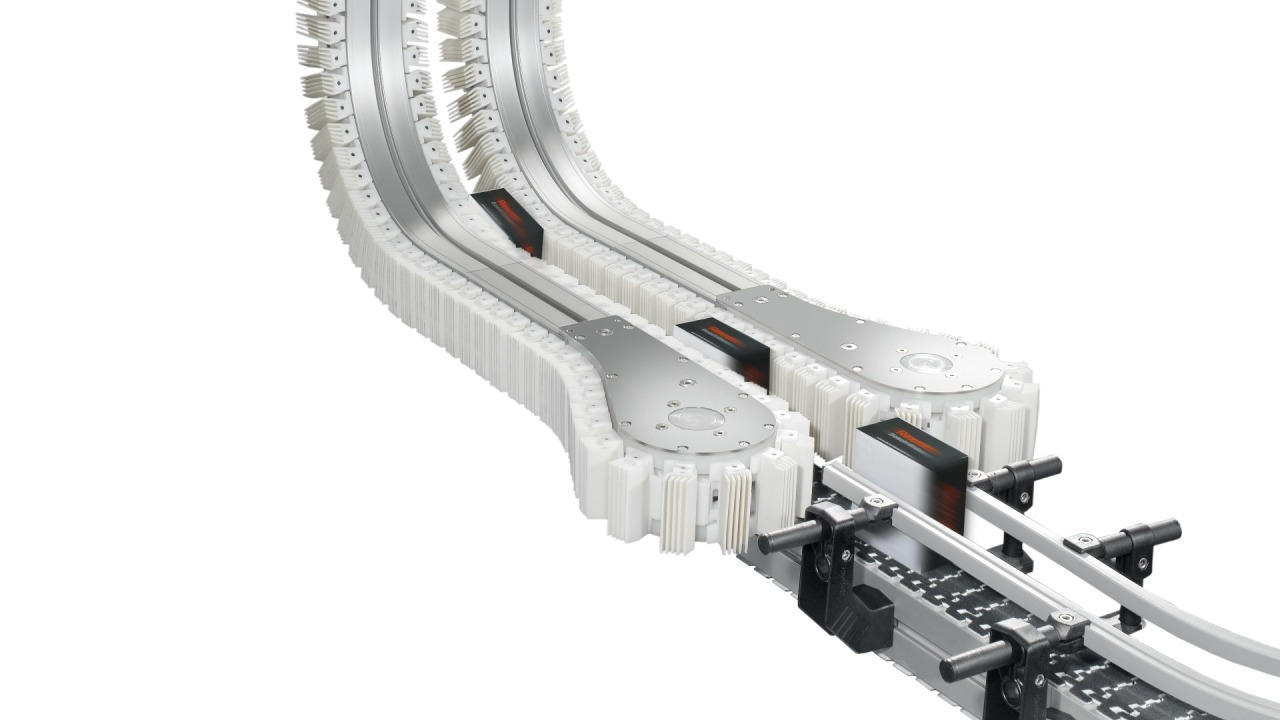

Workpiece pallet system

For the transport of products

- That cannot be transported directly on the chain

- Whose surfaces must not touch each other in the jam

- That are sensitive

- That must be positioned for handling tasks

- With comprehensive functional solutions

Technical key data

- Sizes: 65mm and 90mm

- Chain type: flat chain (white, grey and ESD)

Wedge conveyor

For the transport of products

- That are difficult to convey vertically due to their shape

- That steep vertical inclines (> 30°) cannot be realized because of the center of gravity position

- That would be damaged by side or overpasses due to sensitive surfaces

- That may not slip in 90° inclines or slopes (e.g. with carrier pockets)

- That are to be conveyed without engaging or disengaging

Technical key data

- Product weight: up to 1.5 kg / 34.5 mm

- Speed: up to 60 m/min

- Chain width: 90 mm

Spiral conveyor

- Spiral conveyors enable vertical product transport and serve as buffer storage in the smallest of spaces

- To complement the range of chain conveyors, Bosch Rexroth cooperates with smartPac, a well-known and experienced manufacturer of spiral conveyors

- The spiral conveyors are based on standardized components of the VarioFlow system

Technical key data

- Size: 80-320 mm

- Height difference: max. 3000 mm between inlet and outlet

- Gradient: 5-12°