FLOW RACK ECOFLOW

| Conductivity [ESD] | yes, no |

| Conveyor medium FM | Rollers in plastic, steel, stainless steel |

| Conveyor track width max [BF max] | 892mm |

| Conveyor track width min [BF min] | 200mm |

| Cross tie type [PT] | Tubular cross tie, tubular cross tie with bracket, profile cross tie, double tubular cross tie |

| Division of flow rack depth [TT] | 1000, 1500 |

| Flow rack system depth max [T] | 6000mm |

| Flow rack system depth min [T] | 400mm |

| Flow rack system height max [H] | 2000mm |

| Flow rack system height min [H] | 600mm |

| Flow rack system width max [B] | 1000mm |

| Flow rack system width min [B] | 400mm |

| Foot type [FU] | Leveling foot, LR |

| Front conveyor track projection [UV] | 0, 50 ... 1000 mm |

| Gradient G | 0 ... 10 % (recommended: 6 %) |

| Lateral guide SF | with; without |

| Number of conveyor tracks [NB] | 0 ... 20 |

| Number of return levels [NR] | 0 ... 7 |

| Number of side elements [Typ] | 0, 1, 2 |

| Number of supply levels [NZ] | 1 ... 8 |

| Packaging unit | 1 |

| Rear conveyor track projection [UH] | 0, 50 ... 1000 mm |

| Removal height of the lower supply level max [EH] | 1800mm |

| Removal height of the lower supply level min [EH] | 263mm |

| Roller distance R | 50, 100 mm |

| Slide rail border BG | inside, outside |

| Transportation height max [HT] | 1200mm |

| Transportation height min [HT] | 100mm |

| Version [A] | Disassembled, assembled |

| Weight | 0kg |

- Material supply in the supermarket or directly at the workstation

- For heavy loads

- Full-width rollers for the transport and supply of blister packs or cardboard boxes

- Available as ESD-conductive version

- Design: Fully assembled or as a kit for self-assembly

- Allows for the addition of any desired modules, including cross ties and conveyor tracks as well as individual components

- 1 - Material supply in the supermarket or directly at the workstation

- 2 - For heavy loads

- 3 - Full-width rollers for the transport and supply of blister packs or cardboard boxes

- 4 - Available as ESD-conductive version

- 5 - Design: Fully assembled or as a kit for self-assembly

- 6 - Allows for the addition of any desired modules, including cross ties and conveyor tracks as well as individual components

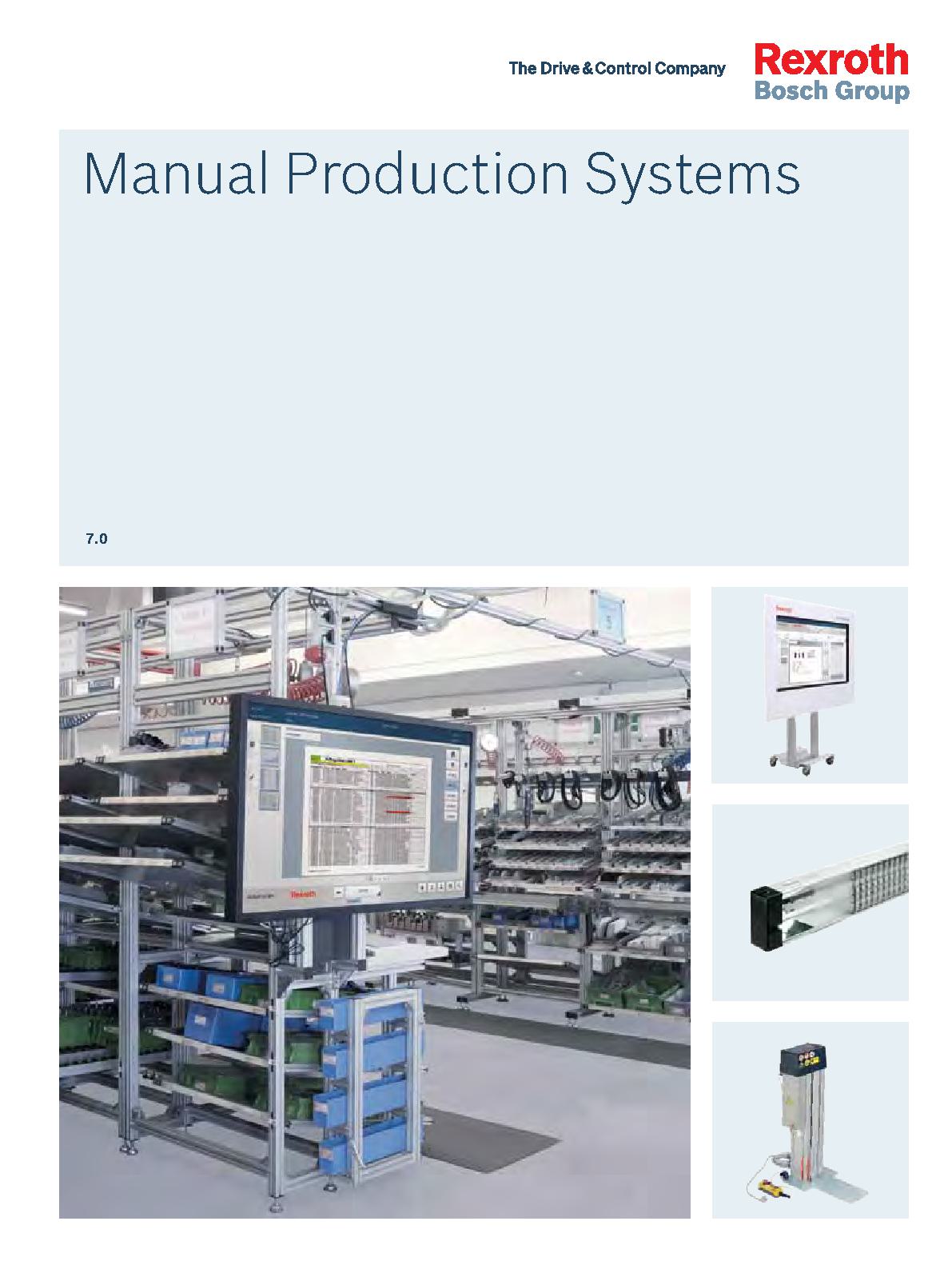

Flow Rack EcoFlow

Allows for the addition of any desired modules, including cross ties and conveyor tracks as well as individual components, Material supply in the supermarket or directly at the workstation, Design: Fully assembled or as a kit for self assembly, For heavy

Allows for the addition of any desired modules, including cross ties and conveyor tracks as well as individual components, Material supply in the supermarket or directly at the workstation, Design: Fully assembled or as a kit for self assembly, For heavy

Flow Rack EcoFlow

Request Quote

How to Find Us

If you have any questions, just fill in the contact form, and we will answer you shortly. If you are living nearby, come visit us.